Isobaric vs SAE

Isobaric vs SAE

Hoses have been used for a few hundred years commonly moving water. However, in the 1920’s and 1930’s demand started to grow for wire reinforced hydraulic hoses primarily in the automotive and transport industry. During WWII there was a move to industry standardization and higher performance to support the war effort and industrial economy.

After the war, the Society of Automotive Engineers developed industry standards which included SAE J517 for hydraulic hoses. The SAE J517 specification is still in use today and has very specific dimensions for the construction of hydraulic hoses. The specification covers various types of braided, spiral and thermoplastic hoses from SAE100R1 to SAE 100R19.

In the early 2000’s global equipment manufacturers needed product performance that exceeded the SAE specifications and started developing hydraulic hoses with significantly better minimum bend radii, better flexibility, lighter weight, and higher impulse cycle life. A global specification was developed in 2006 for a new standard on hydraulic hose which was ISO 18752.

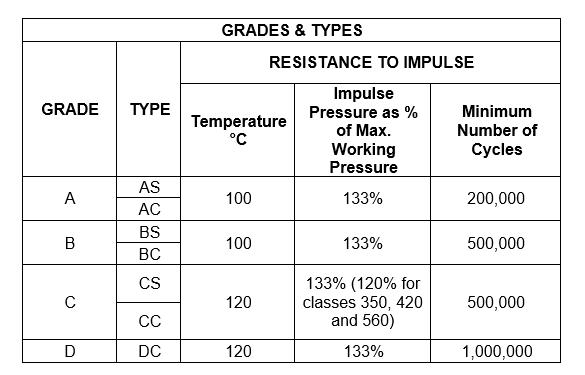

One of the primary differences ISO 18752 has over SAE J517 is the hoses are in working pressure groups and a grade based on impulse cycle testing. Typical ISO 18752 pressure rating groups are hoses in 3,000, 4,000, 5,000 & 6,000psi from ½” to 2” ID. As follows is a table illustrating the performance grade to impulse rating for ISOBARIC hoses.

In the market today, hoses of both specifications are still in use. Texcel offers a complete range of SAE and ISOBARIC braided hose options while offering spiral hoses only in ISOBARIC.